|

|

| Markenbezeichnung: | Small boss |

| Modellnummer: | Zubereitungen für die Herstellung von |

| MOQ: | 5 Stück |

| Preis: | discuss personally |

| Verpackungsdetails: | Schüttgut |

| Zahlungsbedingungen: | T/T, L/C |

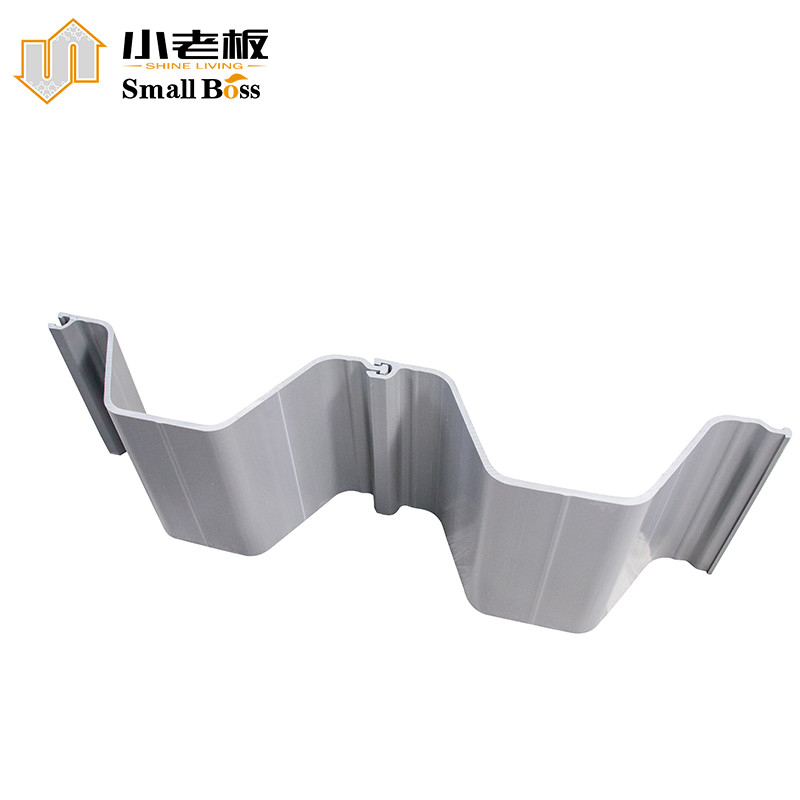

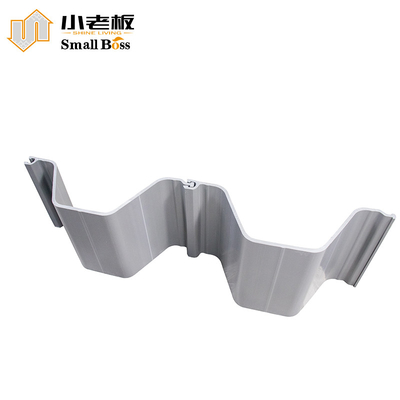

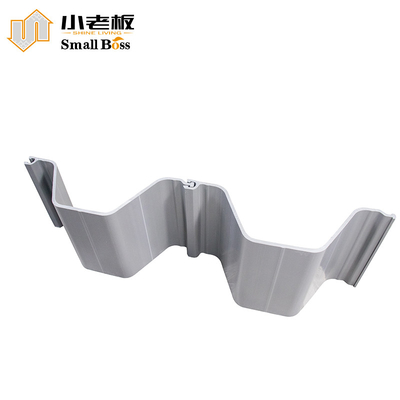

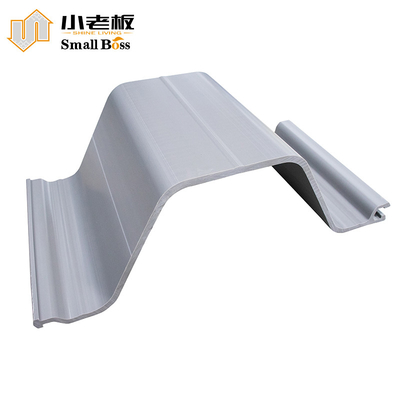

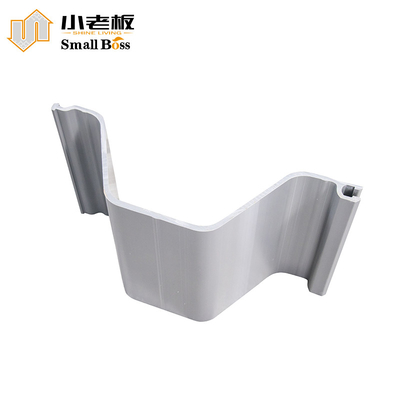

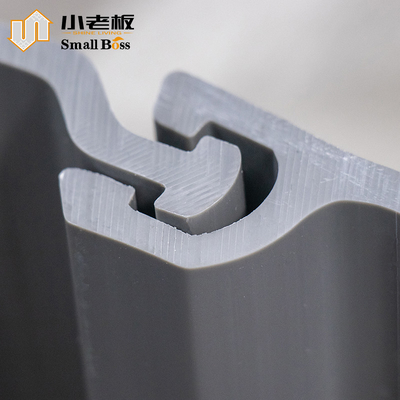

Plastic Sheet Piling Vinyl Sheet Pile Material Vinyl Capping Seawall PVC Vinyl Sheet Pile

Plastic sheet piles are used on softer ground using EMV. They are used on a smaller scale than regular steel piling and are generally used for lower retained heights. Often plastic piling sheets are pre-treated with sealants to create impermeable barriers.

They are often made form recycled materials and are resistant to chemical attack. They are particularly suitable for marine or canal basin walls and flood barrier walls.

Specification:

| Item NO | Section Width | Section depth | Thickness | Length | Color |

| SZ402 | 402MM | 180MM | 9MM | Customization | Customization |

| SZ457 | 457MM | 254MM | 11MM | Customization | Customization |

| SU457 | 457MM | 152MM | 6MM | Customization | Customization |

| SU718 | 718MM | 180MM | 10MM | Customization | Customization |

| SU525 | 525MM | 160MM | 10MM | Customization | Customization |

| SU622 | 622MM | 230MM | 9MM | Customization | Customization |

| SF626 | 626MM | 92MM | 6MM | Customization | Customization |

![]()

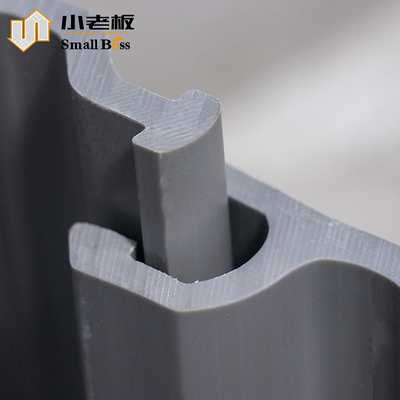

Used to protect places with variable or raised groundwater level, PVC sheet piling efficiently reduces water infiltration as well as secures the terrain against gradual erosion and degradation.Groundwater cut-off Chemical containment, Fluid Seepage Barriers, Protection of Foundation Structures.

The EcoLock retaining systems may be used to separate water reservoirs or groundwater from environmentally challenged places(for instance, in the vicinity of landfills andfactories). Applications include but are not limited to: Groundwater cut-off,Chemical containment,Fluid Seepage Barriers,Protection of Foundation Structures. beachfront protection, coastline protection, road protection, bulkheads construction.

Vinyl Sheet Piles can be utilised for fluid containment or cutoff barriers due to their good chemical resistance and seepage resistance especially if combined with a sealant. Vinyl PVC Sheet Piles can be utilized for water control structures that function by altering the flow of water in a pond, drainage channel or stream. ESC sheet piles have been utilized for water control applications for decades.

Baffle Walls for water or waste water flow control

• River Weirs

• Pond Linings

• Channel Linings for agricultural applications

• River Diversion

• Mining drainage systems

Smallboss has been delivering sheet piling solutions to marine structures. Vinyl PVC Sheet Piles provide an excellent option for a long-lasting structural solution due to their superior corrosion resistance, aesthetic finish, and lightweight profile for easy handling and installation.

The marine applications include:

• Marine Bulkheads & Seawalls

• Tide Walls

• Breakwaters

• Wave Breaks

• Jetty Structures

• Groins

• Scour Protection and Erosion Control

• Retaining Walls

The use of sheet piles reduces the volume of backfill materials by enclosing certain limits exactly as necessary. Employing the material also eliminates the requirement for slope protection works and helps maximize the area when it is limited.

Vinyl sheet pile which can be manufactured to any length specified in the project would make them ideal for the construction of the following: over water or elevated roads,over water or elevated walkways, coastal roads

,jetties or berths, other reclamations.

|

| Markenbezeichnung: | Small boss |

| Modellnummer: | Zubereitungen für die Herstellung von |

| MOQ: | 5 Stück |

| Preis: | discuss personally |

| Verpackungsdetails: | Schüttgut |

| Zahlungsbedingungen: | T/T, L/C |

Plastic Sheet Piling Vinyl Sheet Pile Material Vinyl Capping Seawall PVC Vinyl Sheet Pile

Plastic sheet piles are used on softer ground using EMV. They are used on a smaller scale than regular steel piling and are generally used for lower retained heights. Often plastic piling sheets are pre-treated with sealants to create impermeable barriers.

They are often made form recycled materials and are resistant to chemical attack. They are particularly suitable for marine or canal basin walls and flood barrier walls.

Specification:

| Item NO | Section Width | Section depth | Thickness | Length | Color |

| SZ402 | 402MM | 180MM | 9MM | Customization | Customization |

| SZ457 | 457MM | 254MM | 11MM | Customization | Customization |

| SU457 | 457MM | 152MM | 6MM | Customization | Customization |

| SU718 | 718MM | 180MM | 10MM | Customization | Customization |

| SU525 | 525MM | 160MM | 10MM | Customization | Customization |

| SU622 | 622MM | 230MM | 9MM | Customization | Customization |

| SF626 | 626MM | 92MM | 6MM | Customization | Customization |

![]()

Used to protect places with variable or raised groundwater level, PVC sheet piling efficiently reduces water infiltration as well as secures the terrain against gradual erosion and degradation.Groundwater cut-off Chemical containment, Fluid Seepage Barriers, Protection of Foundation Structures.

The EcoLock retaining systems may be used to separate water reservoirs or groundwater from environmentally challenged places(for instance, in the vicinity of landfills andfactories). Applications include but are not limited to: Groundwater cut-off,Chemical containment,Fluid Seepage Barriers,Protection of Foundation Structures. beachfront protection, coastline protection, road protection, bulkheads construction.

Vinyl Sheet Piles can be utilised for fluid containment or cutoff barriers due to their good chemical resistance and seepage resistance especially if combined with a sealant. Vinyl PVC Sheet Piles can be utilized for water control structures that function by altering the flow of water in a pond, drainage channel or stream. ESC sheet piles have been utilized for water control applications for decades.

Baffle Walls for water or waste water flow control

• River Weirs

• Pond Linings

• Channel Linings for agricultural applications

• River Diversion

• Mining drainage systems

Smallboss has been delivering sheet piling solutions to marine structures. Vinyl PVC Sheet Piles provide an excellent option for a long-lasting structural solution due to their superior corrosion resistance, aesthetic finish, and lightweight profile for easy handling and installation.

The marine applications include:

• Marine Bulkheads & Seawalls

• Tide Walls

• Breakwaters

• Wave Breaks

• Jetty Structures

• Groins

• Scour Protection and Erosion Control

• Retaining Walls

The use of sheet piles reduces the volume of backfill materials by enclosing certain limits exactly as necessary. Employing the material also eliminates the requirement for slope protection works and helps maximize the area when it is limited.

Vinyl sheet pile which can be manufactured to any length specified in the project would make them ideal for the construction of the following: over water or elevated roads,over water or elevated walkways, coastal roads

,jetties or berths, other reclamations.